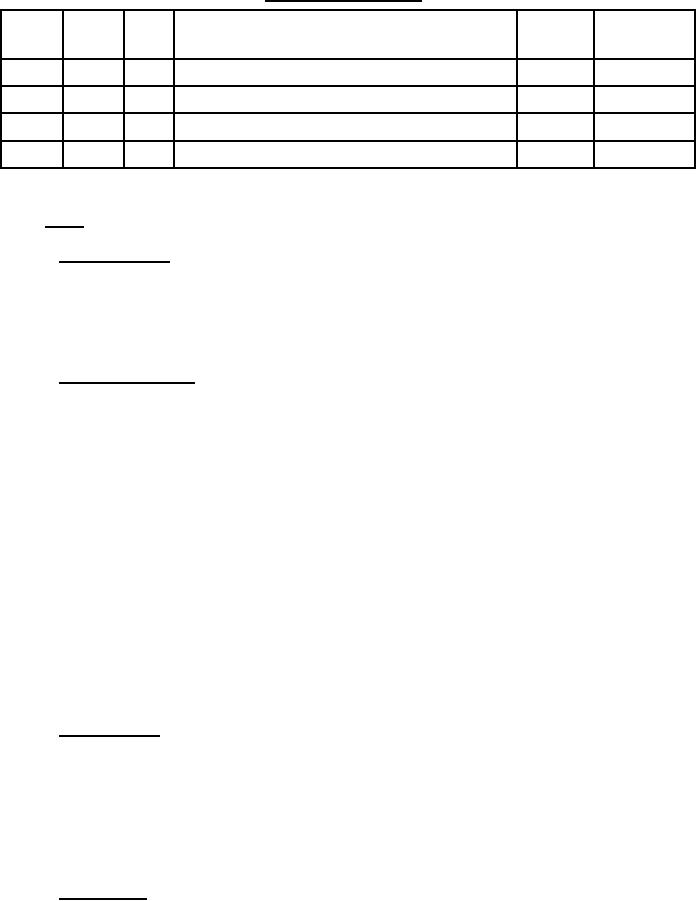

MIL-PRF-52345D

TABLE II. Examination schedule Continued

111

X

X

Female coupling half, internal pipe thread, not

3.3.10 Visual

as specified.

112

X

X

Fish tape not as specified.

3.3.11 Visual

113

X

X

Container not a specified.

3.3.12 Visual/SIE

114

X

X

Material not as specified.

3.4.1

Visual/Doc

115

X

X

Color and markings not as specified.

3.4.2

Visual

Doc = Documentation; SIE = Standard Inspection Equipment

4.5 Tests.

4.5.1 Test conditions. Testing shall be conducted at ambient temperatures between 35 degrees

Fahrenheit (ºF) and 120ºF. Water shall be used as the test medium. The testing shall require a

means of maintaining a pressure of 150 psi on the water filled assembly for a period of at least five

minutes. Failure to maintain the required pressure for the designated time shall constitute reason

for retesting.

4.5.2 Component testing. The component test shall be conducted after the lift test using the

same kit that was subjected to the lift test. From the container components, assemble the

following test system. Take one 4-inch, female, quick-disconnect coupling half and one grooved

to external threaded coupling, and attach the external threaded coupling to the quick disconnect

coupling half. Using pipe coupling clamps, attach one hose assembly to the grooved end of the

external threaded coupling, and attach the tee to the other hose end. With a second hose

assembly and pipe coupling clamps, attach one end of the hose to one leg of the tee and the other

end of the hose to a 4-inch gate valve. To the remaining tee leg, using a pipe coupling clamp,

attach a check valve. The check valve shall be connected to stop the flow. Through the quick-

disconnect coupling half, fill the assembly with water to a pressure of 150 psi, making certain all

air is removed from the system, and close the gate valve. Immediately check the assembly for

leaks and pressure loss. If there are no leaks or pressure loss, maintain the 150 psi pressure for a

period of not less than five minutes. During the time the assembly is under pressure check for

leaks and other defects. At the end of the required time, slowly lower the pressure to ambient and

recover the components. Any damage to components, leaks, or loss of pressure during the five

minute period shall constitute failure of this test.

4.5.3 Container test. The container, with contained components, shall be lifted by mechanical

means utilizing lift provisions. The container shall be lifted not less than 48 inches off the ground

and the lift shall be repeated five times with at least one lift at the maximum speed of the lifting

equipment. At the conclusion of lift five, the container shall be examined for damage, or

deterioration. Open the container and examine the interior and component for mislocation and

other damage. Failure of the container to maintain compartmental and structural integrity through

all lifts shall constitute failure of this test.

4.5.4 Strainer test. The strainer shall be subjected to a 350 gallon per minute flow of liquid

containing solid foreign material between 0.06 and 0.25 inches in diameter for a period of not less

than five minutes. The ratio of solids to liquid shall not be less than one part per hundred by

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business