MIL-PRF-52347D

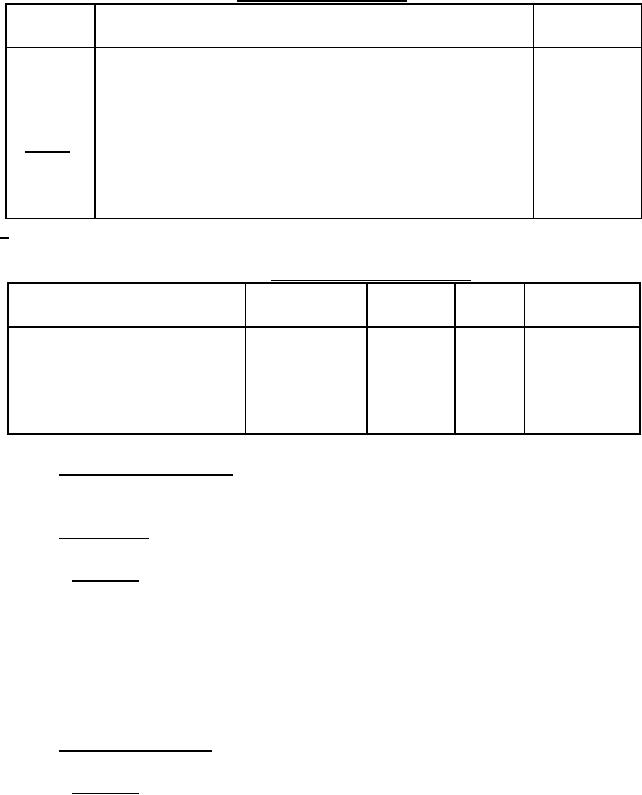

TABLE II. Classification of defects - Continued.

Method of

Category

Defect

examination

114

Wire rope thimbles not as specified (see 3.3.2.9).

SIE

115

Workmanship not as specified (see 3.6).

Visual

116

Metal fabrication not as specified (see 3.6.1).

Visual

Minor:

201

Treatment and painting not as specified (see 3.4).

Visual

203

Identification marking missing, incomplete or illegible

Visual

(see 3.5).

1/ SIE = Standard Inspection Equipment.

TABLE III. Classification of inspections.

Inspec-

First

Conformance

Title

Requirement

tion

article

tests

Wire rope tensile strength

3.3.2.1

4.5.3

X

Manila rope breaking strength

3.3.2.2.

4.5.4

X

Wire rope clamp strength

3.3.2.3

4.5.5

X

Shackle proof strength

3.3.2.4

4.5.6.1

X

X

Shackle breaking strength

3.3.2.4

4.5.6.2

X

X

4.3 Conformance inspection. Conformance inspection shall consist of the examinations of

4.4 and the tests of 4.5.6.1 and 4.5.6.2.

4.4 Examination.

4.4.1 Sampling. Samples from an inspection lot for conformance inspection shall be

selected in accordance with ANSI/ASQC Z1.4. Any redesign or modification of the contractor's

standard to comply with specified requirements shall receive particular attention for adequacy and

suitability. This element of inspection shall encompass all visual examinations and dimensional

measurements of requirements of 3.2 through 3.6 as listed in table II. Noncompliance with any

specified requirement or presence of one or more defects preventing or lessening maximum

efficiency shall constitute cause for rejection.

4.5 Method of inspection.

4.5.1 Materials. Conformance to 3.2 shall be determined by inspection of contractor

records providing proof or certification that materials conform to requirements. Applicable

records shall include drawings, specifications, design data, receiving inspection records,

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business